Plywood

Plywood is arguably the most versatile and durable building material available, and an essential commodity in both interior applications and exterior construction. Over time, we have perfected the manufacture of plywood to provide National with a distinct advantage at every step. Our plywood is synonymous with quality, durability and reliability.

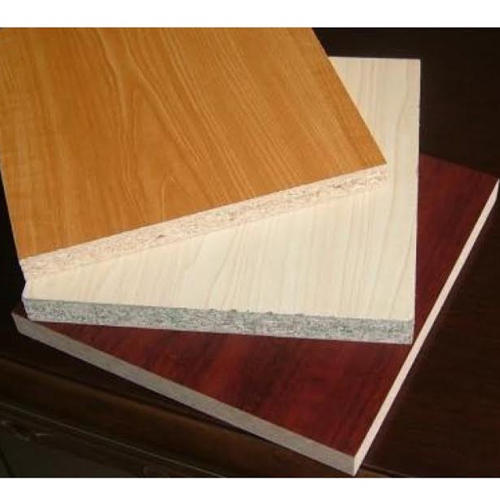

Black boards

Block boards, comprising a core of strips of hardwood within a hardwood frame sandwiched between two or more layers of veneers on either side, are known for their extraordinary strength, dimensional stability and durability. With their immense load bearing capacity, lightweight nature and low bendability, block boards are perfect for furniture building as in tables, shelves, cabinets and benches, and in vertical applications such as wardrobes, doors, panels, partitions, etc.